Isici sesihlungi se-sintered mesh siyisihlungi esiqinile esiphakathi esifakwe kusuka kuzingxenye eziningi ze-wire mesh elukiwe enosayizi othize wembotshana kanye nobubanzi bentambo.Inqubo ye-sintering ibopha izintambo lapho kuxhunywana khona, kwakheka isakhiwo esiqinile, esiqinile futhi esikwazi ukungena.Lesi sakhiwo esiyingqayizivele senza isihlungi se-sintered mesh sibe nokusebenza kahle okuphezulu kokuhlunga, ukungeneka namandla okusebenza.

Izakhi zokuhlunga ezinezikhala ze-Sintered zinikeza izixazululo ezinhle kakhulu zokuhlunga zezinhlelo zokusebenza ezihlukene ezifana nokuhlunga kwegesi, ukuhlunga uketshezi ngisho nokuhlukaniswa koketshezi oluqinile.Isici sokuhlunga singakwazi ukuhlunga ukungcola nezinhlayiya ezincane njenge-micron engu-1 ububanzi.Ukwengeza, isakhiwo esiyinhloko siqinisekisa ukusatshalaliswa okulinganayo kwenqubo yokuhlunga, okuholela ekusebenzeni kahle kokuhlunga kanye nokwehla kwengcindezi ephansi.

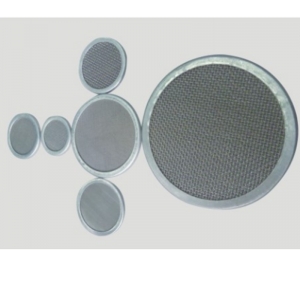

Izinto zesihlungi se-Sintered mesh ziklanywe ngezinhlobonhlobo zosayizi abajwayelekile nabangokwezifiso, umumo namabanga okuhlunga.Ungakhetha phakathi kwezilinganiso zokuhlunga okuzisholo ukusuka ku-1μm kuye ku-300μm kanye nezilinganiso zokuhlunga eziphelele zisuka ku-0.5μm kuye ku-200μm.Inhlanganisela ehlukene yamadayimitha embotshana kanye nentambo kuma-elementi okuhlunga anezikhala ezisinki zinikeza ukuguquguquka kokuhlunga okuphumelelayo nangempumelelo ezinqubweni ezihlukene zezimboni.

Izinto zesihlungi se-metal sintered mesh zenziwe ngezinto ezimelana nokugqwala zekhwalithi ephezulu njengensimbi engagqwali, i-Hastelloy, nama-titanium alloys.Amandla nokuqina kwento esebenzayo iholela empilweni ende kanye nezindleko zokuyilungisa eziphansi kunezinye izihlungi zemidiya.Izihlungi ze-Sintered mesh nazo zilula kakhulu ukuzihlanza futhi zidinga ukushintshwa kancane kancane, ukunciphisa isikhathi sokungasebenzi komsebenzisi nokwandisa umkhiqizo.

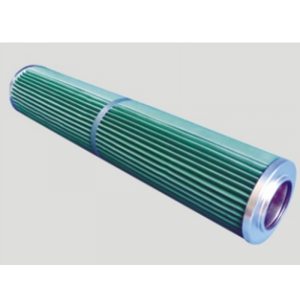

Izinto zokuhlunga ezinezikhala zensimbi ezisikiwe ziyahlukahluka futhi zingenziwa ngezifiso izidingo ezithile zokuhlunga kwezimboni.Ingafakwa ezindaweni ezihlukene zokuhlunga, iqinisekise ukuthi isebenza ezinhlelweni ezihlukahlukene zokuhlunga.I-elementi yokuhlunga ingase futhi isebenze njengosekelo lwama-elementi okuhlunga ahlukene, inikeze izinga eliphezulu lokuvikela.

Izici zomkhiqizo

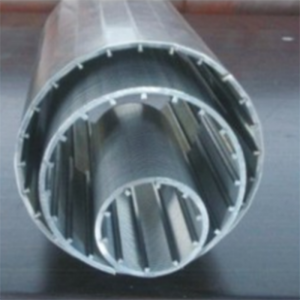

1)I-standard mesh plated sintered inesendlalelo esivikelayo, isendlalelo esinembayo sokulawula, isendlalelo sokuhlakazeka kanye nesendlalelo esiqinisa izendlalelo eziningi.

2) Ukungena kahle, amandla aphezulu, ukumelana nokugqwala okuqinile, ukuhlanza okulula nokulwa nokuhlanza, akulula ukulimaza, akukho lutho oluvaliwe.

Imininingwane yobuchwepheshe

1) Indaba:1Cr18Ni9T1,316,316L

2) Ukunemba kokuhlunga:2~60µm

3) Ukusetshenziswa lokushisa: -20 ~ 600 ℃

4) Ingcindezi ephezulu yokuhluka: 3.0MPa

5) Inombolo yesendlalelo: 2-7layer

6) Ubukhulu kungenziwa ngezifiso ngokuvumelana nezidingo zamakhasimende